How to Ensure Reliability and Business Efficiency

Businesses and individuals rely on scales for everything from manufacturing products to weighing food. However, a scale that has not been regularly calibrated or has been handled improperly can give incorrect readings. In this blog, we’ll explore the top three reasons to calibrate and maintain your scales.

regularly calibrated or has been handled improperly can give incorrect readings. In this blog, we’ll explore the top three reasons to calibrate and maintain your scales.

- Accuracy

Initially, a scale is calibrated to ensure it provides readings within a specific industry standard of measurement. After a certain length of time, or after a period of continuous use, the weighing element may not return to its original position. When this occurs, the scale will display inaccurate measurements.

The environment surrounding a scale is also a factor. If a scale is in an area that contains fluid or dust, a buildup of these or other substances can affect the scale’s accuracy. Similarly, if a scale is located where there are temperature changes, static electricity, vibrations, humidity, or voltage surges, it may provide erroneous measurements.

If your business relies on the daily use of scales, their accuracy has critical business impact. Regularly scheduled calibration and maintenance can prevent weighing errors and ensure accurate, reliable measurements.

- Cost savings

How important is an accurate weight to your business? A scale that provides incorrect measurements can have major financial consequences. For example, an inaccurately weighed package of goods could be more expensive to ship, resulting in lost profits. Scales that weigh food inaccurately could lead to food waste, which costs money and lost time in restocking. Companies that can’t afford even the smallest inaccuracy, such as those in the pharmaceutical industry, may need more frequent scale calibrations to ensure precision and safety. But all companies that rely on scales to conduct business should schedule regular calibrations. Calibrating your scale not only ensures you are sending the correct weight to your customers or suppliers, but that you are receiving the correct weight of goods from suppliers or vendors.

- Regulatory compliance

Many industries, such as pharmacy and agriculture, are subject to regulatory compliance standards. During regulatory inspections, one of the critical areas to be checked is the accuracy of measuring instruments. If the scales being used do not meet the industry standard and regulatory requirements, a company could incur heavy penalties. Having your scales calibrated on a regular basis is necessary to meet compliance standards and helps meet ISO requirements.

Create a Calibration Plan

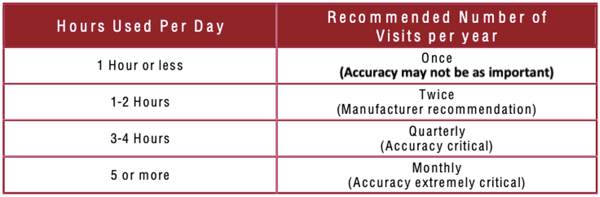

Businesses that depend on accurate measurements of weight need both consistent calibrations and preventative maintenance to extend the life of their scales. The frequency of calibration will depend on several factors—how often the scale is used, the surrounding environment, manufacturer’s recommendations, and whether an exact weight measurement is essential to your business. Some scales need to be calibrated monthly, and others only once per year. In all cases, it is important to put a plan in place for regular calibration and preventative maintenance.

If your equipment has not been calibrated recently, we recommend scheduling a calibration service. Alliance Scale offers professional and trust-worthy scale servicing for a variety of equipment. Contact us today for more information.